PRODUCT

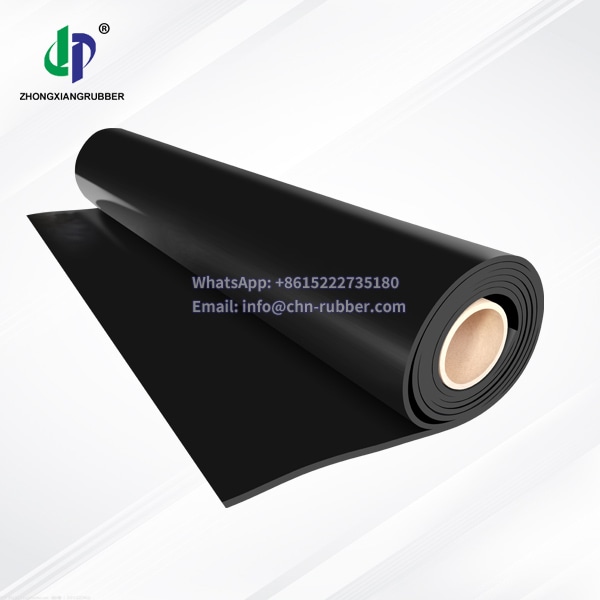

2.5Mpa resistant rubber sheet SBR material black 1.6g/cm³

Reference Standard: ASTM standard

Quality Certification: SGS RoHS2.0 REACH

Thickness: 3mm; Thickness over 15mm, available in sheet form

Specification (W/L):

Width: Standard 1mtrs 1.2mtrs 1.4mtrs 1.5mtrs 1.6mtrs 1.8mtrs 2.0mtrs

Length: Standard 5mtrs 10mtrs 15mtrs 20mtrs. Available upon request

Color: Black

Packing Information: Regular / Up to your choice

Packed with plastic film.

Packed with plastic film and with PP woven bag.

Wooden pallet.

According to the customer request, fixed-length or heavy package.

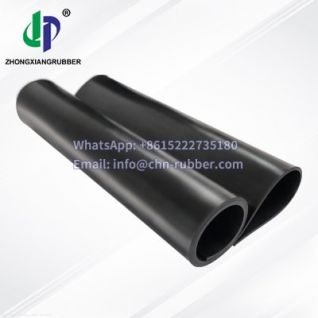

Product Supply Form: Roll / Sheet or Plate / Strip

Get more information:

Email: info@chn-rubber.com

P.H & Wechat: 008615222735180

General Resistant Rubber Sheet – a dependable barrier material engineered for enhanced endurance across diverse operational conditions. This sheeting is formulated not for extreme niche challenges, but to provide a significantly elevated level of protection against the common, everyday stressors that degrade standard rubber materials. Built on a foundation of compounded resilience, the maintains its structural and functional integrity longer, offering reliable performance where physical wear, incidental contact with various substances, and general operational duress are factors. It represents a practical upgrade for applications demanding more robustness than basic GP rubber can provide, ensuring longevity and consistent defense for your components and surfaces.

SBR RUBBER SHEET TECHNICAL PARAMETERS

| SBR RUBBER SHEET TECHNICAL PARAMETERS | ||||||||

| Code | Specific Gravity | Hardness (+/-5) | Tensile Strength | Elongation at break | Colour | Finish Type | ||

| g/cm³ | Shore A | Mpa | (min) % | |||||

| STANSDARD | ASTM D397 | ASTM D2240 | ASTM D412 | ASTM D412 | --- | --- | ||

| ZXZRS20101S | 1.6+/-0.05 | 70 | 2.5-3 | 180 | Black | Smooth in both sides OR 1/2 With sides cloth OR 1 side With anti-slip texture | ||

| ZXZRS20201S | 1.6+/-0.05 | 70 | 2.5-3 | 180 | Red | |||

| ZXZRS20401S | 1.6+/-0.05 | 70 | 2.5-3 | 180 | Green | |||

| ZXZRS20001S | 1.6+/-0.05 | 70 | 2.5-3 | 180 | Customized production according to demand | |||

| Note: 1MPa =10.2 Kg/cm² 1N/mm =1.02 Kg/cm |

||||||||

| SPECIFICATION | ||||||||

| Item | Thickness | Width | Length | Insertion | Weight | |||

| mm | m | m | Material | Layers | KGS/m² | lb/ft² | ||

| 1 | 1 | Standard width | 5m/10m/15m/20m | Nylon canvas / Mesh fabric / Nylon mesh fabric / Encrypted canvas | / | 15.36 | 3.15 | |

| 2 | 1.5 | Standard width | 5m/10m/15m/20m | / | 24.96 | 5.11 | ||

| 3 | 1.7 | Standard width | 5m/10m/15m/20m | 1PLY | 28.80 | 5.90 | ||

| 4 | 2 | Standard width | 5m/10m/15m/20m | 1PLY | 34.56 | 7.08 | ||

| 5 | 3 | Standard width | 5m/10m/15m/20m | 1PLY | 53.76 | 11.01 | ||

| 6 | 4 | Standard width | 5m/10m/15m/20m | 1PLY | 72.96 | 14.94 | ||

| 7 | 5 | Standard width | 5m/10m/15m/20m | 2PLY | 92.16 | 18.87 | ||

| 8 | 6 | Standard width | 5m/10m/15m/20m | 3PLY | 111.36 | 22.81 | ||

| 9 | 8 | Standard width | 5m/10m/15m/20m | 4PLY | 149.76 | 30.67 | ||

| 10 | 10 | Standard width | 5m/10m/15m/20m | 5PLY | 188.16 | 38.54 | ||

| 11 | 12 | Standard width | 5m/10m/15m/20m | 8PLY | 226.56 | 46.40 | ||

| 12 | 15 | Standard width | 5m/10m/15m/20m | 10PLY | 284.16 | 58.20 | ||

| 13 | 20 | Standard width | 5m/10m/15m/20m | ≥10PLY | 64.00 | 13.11 | ||

| 14 | 25 | Standard width | 5m/10m/15m/20m | ≥10PLY | 80.00 | 16.38 | ||

| 15 | 30 | Standard width | 5m/10m/15m/20m | ≥10PLY | 96.00 | 19.66 | ||

| 16 | 50 | Standard width | 5m/10m/15m/20m | ≥10PLY | 160.00 | 32.77 | ||

Tabulated weight values are provided for informational purposes only. As dimensional specifications of rubber sheets are fully customizable per project requirements, actual weights may vary accordingly. For precise weight calculations tailored to your application, please submit specific technical parameters to our engineering team.

Insertion materials:

|

|

|

|

| Nylon canvas | Mesh fabric | Nylon mesh fabric | Encrypted canvas |

TARGET APPLICATIONS

- 1. Upgraded Gasketing & Sealing: Fabricating more durable seals, gaskets, and strips for equipment housings, access panels, and mating surfaces requiring better longevity against compression and incidental exposures.

- 2. Resilient Surface Protection: Lining work stations, tool chests, carts, and high-contact zones to offer superior protection against impacts, scratches, and general wear-and-tear compared to basic matting.

- 3. Durable Component Manufacturing: Creating tougher pads, bumpers, vibration isolators (where oil/fluid contact is possible), impact strips, and protective sleeves for industrial equipment and assemblies.

- 4. Enhanced Workshop & Maintenance Area Use: Serving as long-lasting benchtop covers, floor runners in moderate traffic areas, or protective curtains where improved resistance to wear and occasional fluid drips is beneficial.

- 5. Intermediate-Duty Chute & Hopper Lining: Providing a cost-effective lining option for handling moderately abrasive materials or where occasional contact with process fluids necessitates more than standard rubber offers.